What is the CNC technology for CNC machining? "CNC" is a computer digital control technology in English, abbreviated as CNC. The CNC machining method belongs to a type of carving and shaping, and precision part machining is a widely used accessory in industries such as automobiles, communications, healthcare, clocks, mobile phones, computers, etc. Unlike ordinary parts, precision parts are more precise and more suitable for industries with higher precision requirements. The processing of mechanical parts generally refers to the sum of the assembly process of the part number and machine cry. Other processes are called auxiliary processes, such as transportation, storage, power supply, equipment maintenance, etc.

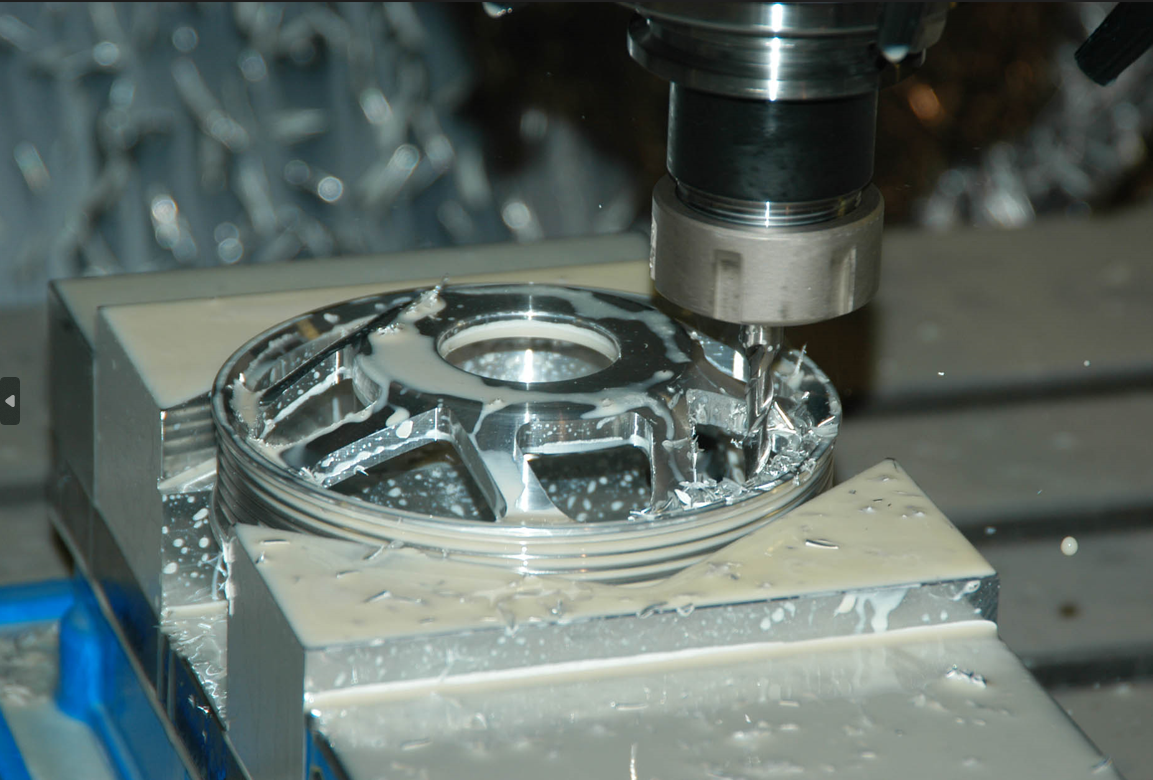

Traditional machining is accomplished through manual operation of ordinary machine tools. During the machining process, the machine tool is shaken by hand to cut metal and the accuracy of the product is measured using tools such as calipers. Modern industry has used computer numerical control machine tools for operation, which can be operated by technicians. The programmed program automatically processes any product and part.

It is a method of using digital information to control the movement and machining of machine tools, using CNC technology to control the machining of machine tools, or a machine tool equipped with a CNC system is called a CNC machine tool. Among them, the CNC machine tool system includes: CNC machine tool device, programmable controller, spindle drive device, and feed device. CNC machine tools are highly integrated products of mechanical, electrical, hydraulic, pneumatic, optical, and other fields. In order to control the machine tool, geometric information is needed to describe the relative motion between the tool and the workpiece in CNC machining. Process information is used to describe some process parameters that must be mastered in machine tool machining, such as feed rate, spindle speed, spindle forward and reverse rotation, tool change, coolant switch, etc., which are stored in a certain format of machining files (i.e. CNC machining programs) on information carriers (such as disks, hot stamping tapes, magnetic tapes, etc.). Then, the CNC system reads the machine tool, or directly inputs it through the keyboard of the CNC system or through communication input. Through decoding, the machine tool moves and processes parts.

Modern CNC machine tools are typical electromechanical products, which are the technological foundation of the new generation of production technology and computer integrated manufacturing. Either directly input through the keyboard of the CNC system, or through communication input, decode to move the machine tool to process parts. Modern CNC machine tools are the foundation of the new generation of cow production technology and computer integrated manufacturing technology. Either directly input through the keyboard of the CNC system, or through communication input, decode to move the machine tool to process parts. Modern CNC machine tools are typical electromechanical products, which are the technological foundation of the new generation of production technology and computer integrated manufacturing. The development trend of modern CNC machine tools is high-speed, high-precision, high reliability, multifunctional, composite, intelligent, and open structure. The main development trend is to develop intelligent and fully functional universal CNC devices with open software and hardware structures. CNC technology is the foundation of machining automation and the core technology of CNC machine tools. Its level is related to the strategic position of a country and reflects the overall strength of the country. It has developed with the development of information technology, microelectronics technology, automation technology, and detection technology. CNC machining center is a type of CNC machine tool with a tool library, which can automatically change tools and perform various machining operations on workpieces within a certain range. Due to the centralized and automatic completion of multiple processes by the machining center, human operational errors are avoided, greatly reducing the time for workpiece clamping, measurement, and machine tool adjustment. CNC machining, as well as greatly improving the turnover, handling, and storage time of workpieces, greatly improves the efficiency of CNC machining

Post time: May-24-2024