-

Surface Treatment Services–meet the corrosion resistance, wear resistance

Surface treatment is a method of artificially forming a surface layer with different mechanical, physical and chemical properties from the substrate on the surface of the substrate, is to clean, sweep, deburr, degrease, and descale the surface of the workpiece surface.

The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product and for machined parts. -

Machining of aluminum parts–more than 10 years of processing experience

Aluminum processing is widely used in various industries such as electronic, mechanical equipment and automation .,etc. Aluminum is one of common material in machining parts with durable, lightweight, extensible, low-cost, easy to cut and other characteristics.

Due to the wide range of mechanical properties such as non magnetic,ease of processing, corrosion resistance, conductivity, and heat resistance, aluminum processing (aluminum turning and milling) is increasingly used in the field of mechanical engineering for custom machining parts -

CNC Turning Services– engaged in multi-variety and small-batch mechanical parts

CNC Turning is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disk parts, inner and outer conical surfaces of arbitrary cone angles, complex rotary inner and outer curved surfaces, cylinders, conical threads, etc. According to the pre-programmed processing program, it can process precision parts such as grooving, drilling, reaming, reaming and boring.

-

CNC Milling Services–engaged in the custom processing

K-TEK has successively introduced Japan Brother, American BRIDGEPORT, and German DMG high-precision CNC machine tools to meet the processing needs of customers for various precision parts.

-

K-Tek Overview Brochure

K-Tek specialized in precision machinery parts processing,we can customize the production of all kinds of precision machinery parts according to the requirements of customers, processing accuracy can be controlled within ±2 um, surface roughness (√) control in Ra0.2. products related to machinery, electronics, automation, automotive, medical, new energy and other fields.

-

Stainless steel processing service

Stainless steel parts are widely used in different industries. It has the characteristics of not easy to rust, corrosion resistance, heat resistance, wear resistance and easy to be polish .It is an important material choice for machining parts.

-

Plastic processing service–rich experience in processing parts

Engineering plastics have excellent comprehensive properties, high rigidity, low creep, high mechanical strength, good heat resistance, and good electrical insulation. They can be used for a long time in relatively female chemical and physical environments, and can replace metals as engineering structural materials.

-

Steel processing service–professional precision machine parts

Steel is one of the most commonly used materials for construction machinery parts. It has a variety of properties, and its main components are iron and carbon. Steel is refined iron. We usually call it iron alloy steel. In order to ensure its strength and plasticity, the carbon content generally does not exceed 1.7%. In addition to iron and steel, the main elements of steel are silicon, carbon manganese, sulfur, phosphorus and so on.

-

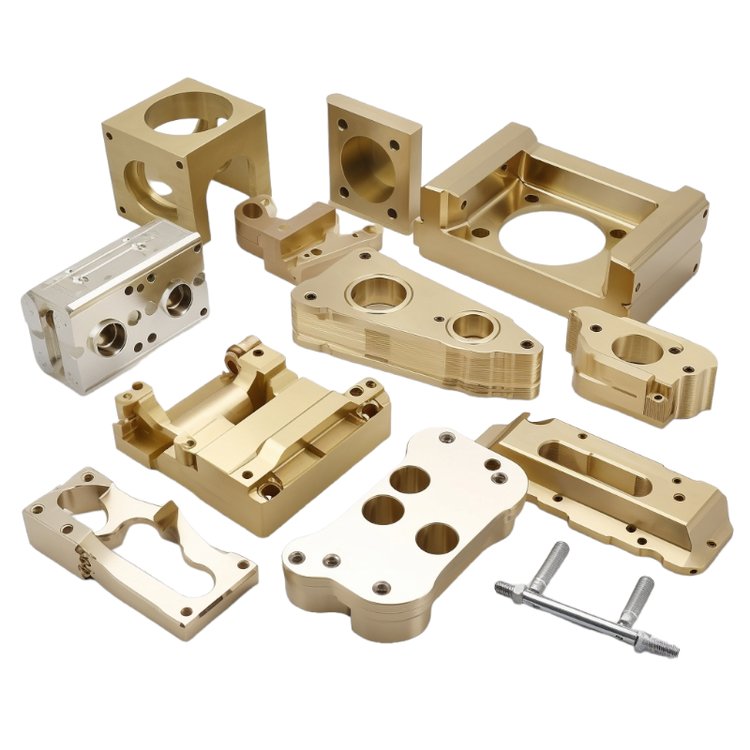

Copper processing service–focusing on a variety of small batch production

Copper is one of the first metals discovered by man, and one of the better pure metals. It has the following characteristics: slightly hard, extremely tough, wear-resistant, good ductility, good thermal and electrical conductivity ,at the same time, the copper alloy has good corrosion resistance, is stable in dry air, durable and can be regenerated. Therefore, the excellent comprehensive properties of copper and copper alloy processing materials have been widely good evaluated in the fields of electronics, machinery manufacturing, communications, automobiles, instrumentation, and military industries.

-

5 Axis CNC Machining Services

K-TEK has introduced world’s ultra precision machine-DMG 5-Axis Machining Center since 2018 in order to meet high requirements on different industries.5-axis machines rely on a tool that moves in five different directions — X, Y, and Z, as well as A and B, around which the tool rotates. Using a 5-axis CNC machine lets operators approach a part from all directions in a single operation, eliminating the need to manually reposition the workpiece between operations. 5-axis CNC machining saves time and is ideal for creating complex and precise parts like those found in the medical oil and gas, and aerospace industries. Indexed 5-axis machining is great for manufacturing spatial surface, special-shaped, hollow, punching, oblique hole and oblique cutting.