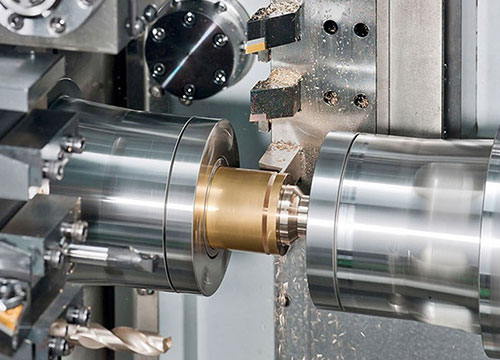

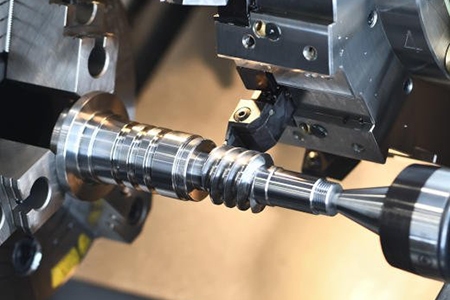

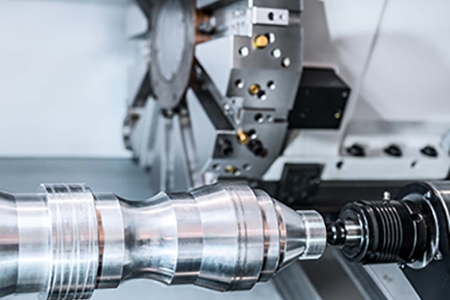

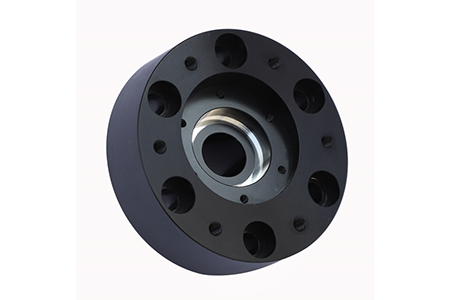

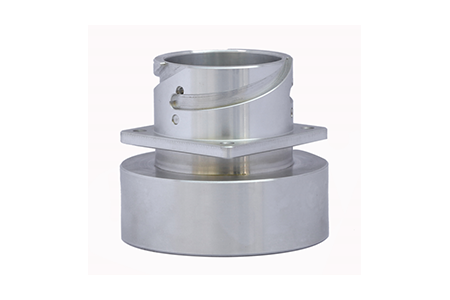

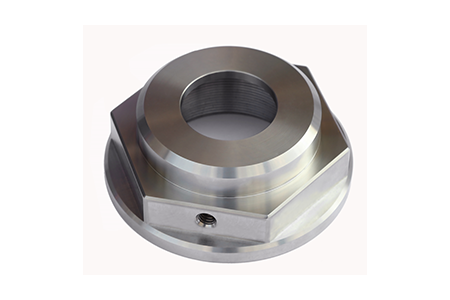

CNC Turning Services

CNC Turning is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disk parts, inner and outer conical surfaces of arbitrary cone angles, complex rotary inner and outer curved surfaces, cylinders, conical threads, etc. According to the pre-programmed processing program, it can process precision parts such as grooving, drilling, reaming, reaming and boring.

±0.005MM (√)Ra0.2

CNC Machine Has the Following Characteristics

● High processing precision and stable processing quality;

● It can carry out multi-coordinate linkage, high degree of automation, and can process parts with complex shapes;

● When replacing the processing parts, generally only need to change the NC program, which can save production preparation time and improve efficiency;

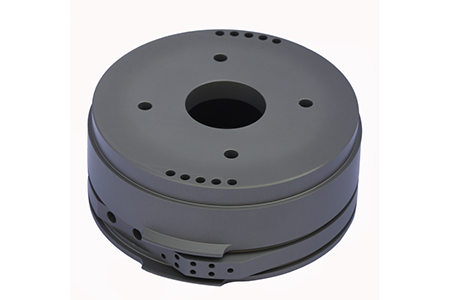

Precision Machined Parts With High Quality Guaranteed

K-TEK has advanced processing equipment, excellent engineering team, and efficient operation mode. It provides customers with high-quality and efficient CNC turning services at competitive prices, and transforms meticulous engineering design drawings into various precision parts.

Custom machining of lathe parts

Precision Requirements for Custom Turning Parts

|

Machining accuracy |

|

|

can generally meet the requirements |

|

| machining accuracy | ±0.005 MM |

| (√) | Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

|

Mini Order Quantity(MOQ)≥1 |

|

Machining Commonly Used Materials & Surface Treatment

Different precision parts can use different materials according to the design requirements of the product. We can process various materials and surface treatments to meet customer requirements. Common materials and surface treatments are as follows:

|

Common materials & Surface treatment |

||

|

Common Materials |

Steel |

20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, etc. | ||

|

Aluminum |

LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, etc. | ||

|

Stainless Steel |

SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H, , SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, etc. | ||

|

Copper |

T2, TU1/2, TP1/2, , Brass, Copper, Bronze, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, etc. | ||

|

Plastic |

PEEK, PEEK1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, PET, PET+30%GF, PC, PC+30%GF, Nylon, ABS, ESD225/420/520, etc. | ||

|

Surface treatment |

Clear Anodize, Black Anodize, Hardness Anodize, Blue/Red Anodize, Chromate Plating, QPQ | |

| Electroless Nickel/Nine/Chromium Plate, Black Oxide, Silver\Golden plating, Sanded, DLC | ||

| Orbital Sanded, Passivated, TIN PlatingTungsten Carbide Coating, Polyurethae coating, etc. | ||