| Equipment brand | BRIDGEPORT、 Brother |

| Type | GX800、FVP-800A |

| Process range | 1300*700mm |

| Qty | 26 set |

| Machinery Axis | 3,4,5, |

| Certificate: IS09001 | 2015 |

| Experience | 16 years |

What is CNC milling?

CNC milling is a machining process that combines computer numerical control machining systems and a multi-point cutting tool or milling cutter. Sophisticated CNC milling machines can have 5 or more axes of independent motion to make more complex shapes or to avoid having to move the workpiece to a separate machine.

What are the Advantages of Computer Numeric Control For CNC Milling?

All of these movements of CNC mills rely on Computer Numeric Control, which is a computer program derived from a 3D digital file of the desired finished part.

Early automated machine tools relied on punch cards to control their basic movements in a systematic fashion. This technology worked but it was a slow and cumbersome system and punch cards could not be modified once made. These were later replaced by magnetic tapes, disk drives and now fully digital instructions in G-Code.

How Does CNC Milling Help You Get Great Parts?

Symmetrical parts that are essentially round or radial are best machined on a CNC turning center for maximum efficiency and precision. But most parts we work with are not round or symmetrical so they must be machined on a mill. Multi-axis mills are unrivalled for creating square shapes, bevels, angles, slots and complex curves – any subtractive machining process can be done on a mill, including making round shapes.

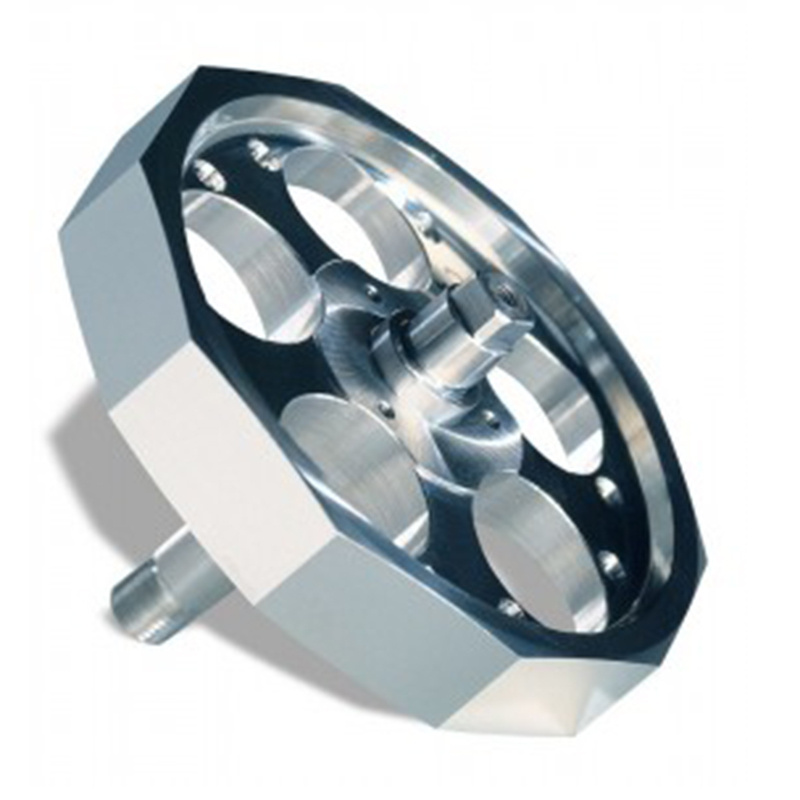

(K-Tek’s CNC, CNC milling workshop)

We specialize in machine parts that are related to various industries including machinery, automation, aerospace, automotive, electronics, medical and other fields.

Our main processing service:

1)5 Axis CNC Machining /CNC Milling/CNC Turning;

2) Lathe /EDM/ WEDM-HS, LS

3) Heat treatment /Surface treatment

Please don’t hesistate to send us requests to sales@k-tekmachining.com.

Post time: Dec-13-2023